John Handley Bearings introduces a revolutionary new range of split cylindrical roller bearings

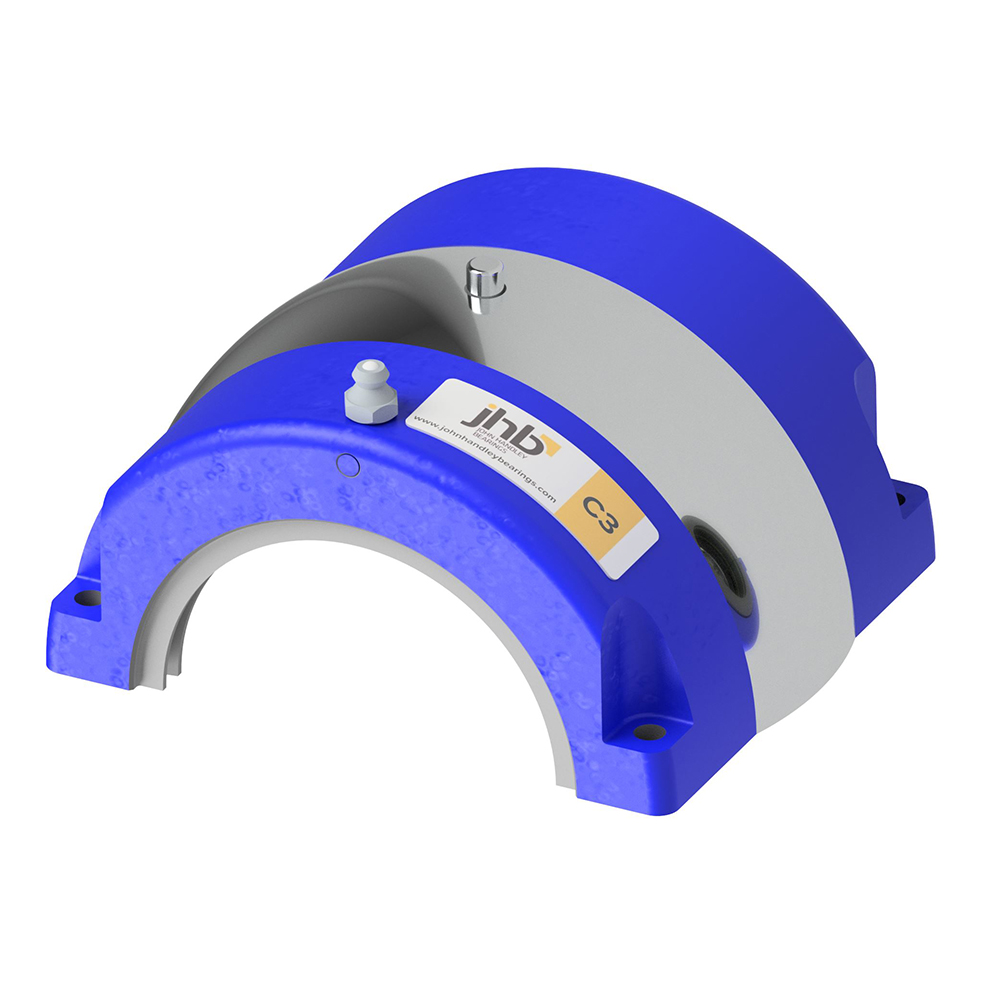

John Handley Bearings (JHB) launched their revolutionary new range of split bearings at the BearingNet User Meeting in Warsaw, Poland last month. This new range of split roller bearings is already creating quite a buzz within the bearings world with talk of vastly increased capacities through the use of innovative new components; indeed, EIGHT new patents have been filed for the various new parts within the unit. Here we take an exclusive look at the JHB Split Bearings and investigate just why it is causing such a stir within the industry.

Moving with the times

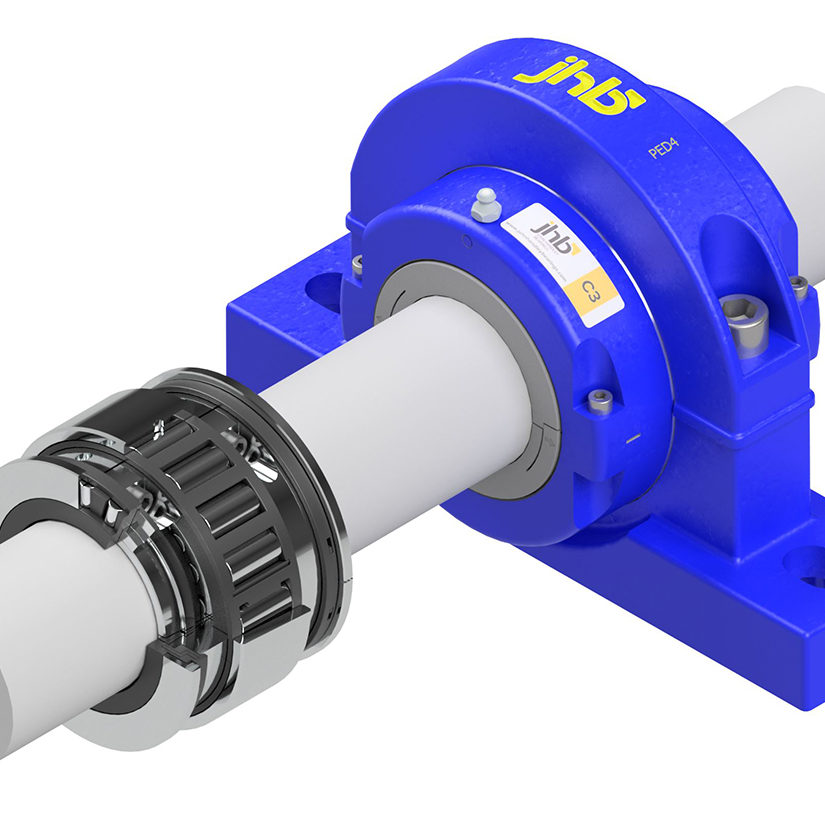

The split roller bearing is an industry stalwart. It is known throughout the engineering world for its ability to improve efficiency, reduce downtime, increase production and is admired for its time-saving attributes and simplicity of design. It is almost essential for applications where the bearing location is trapped or access is limited. However, with very few developments or upgrades since its invention in 1907 it is starting to lag behind an ever-increasing modern demand for higher capacities. With the monopoly for quality split roller bearings held by just a handful of large bearings companies, design engineers have had little choice but to work within certain parameters.

JHB look set to break this paradigm with a new product that does everything the original split bearing did whilst offering significantly more in the way of capacity, flexibility and simplicity of fitting & maintenance.

A Collaborative Approach

JHB is part of The Bowman Group of companies and has had the luxury of being able to partner with the 3D printing division of the group, Bowman Additive Production, to explore the possibility of how they might improve and innovate on a component whose design has remained largely unchanged for the better part of 110 years. The end product is something that is almost inconceivably advanced compared to anything currently available.

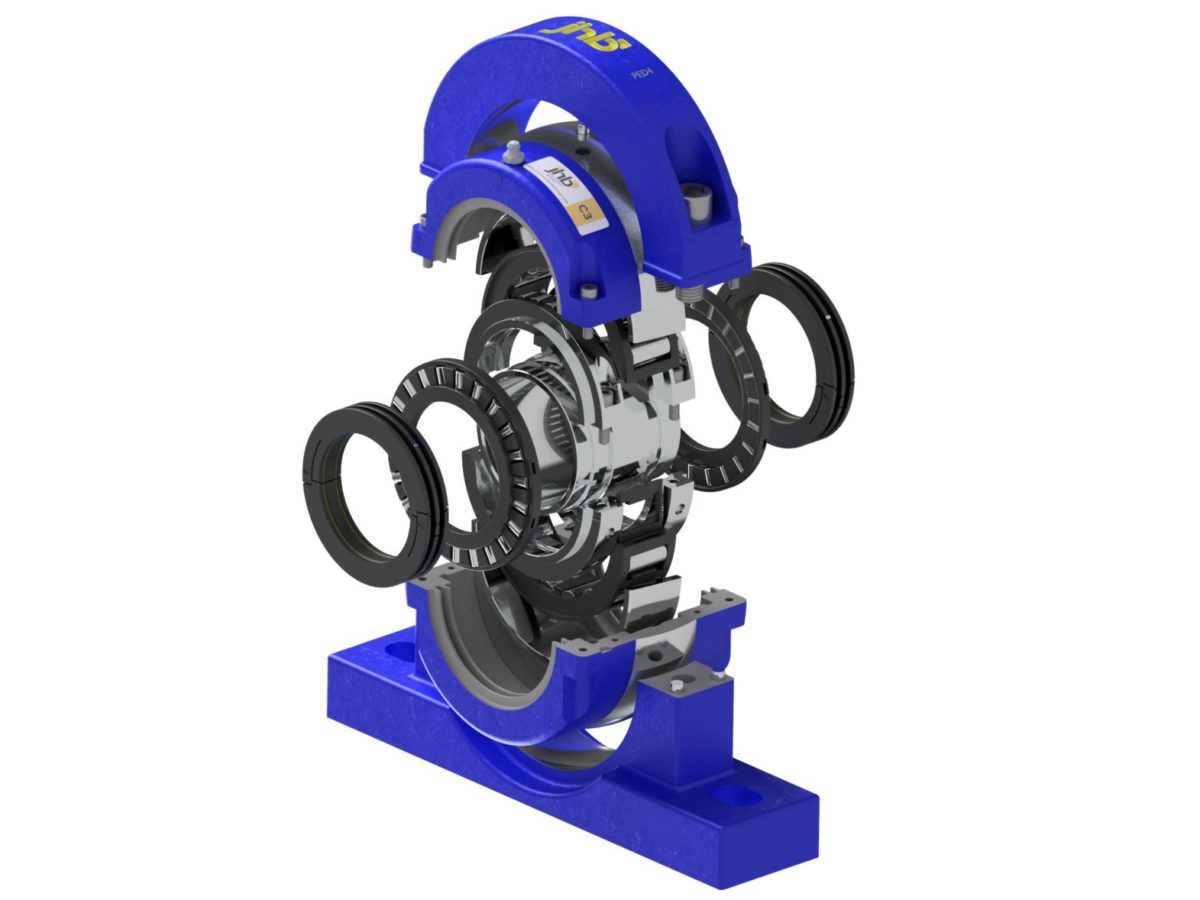

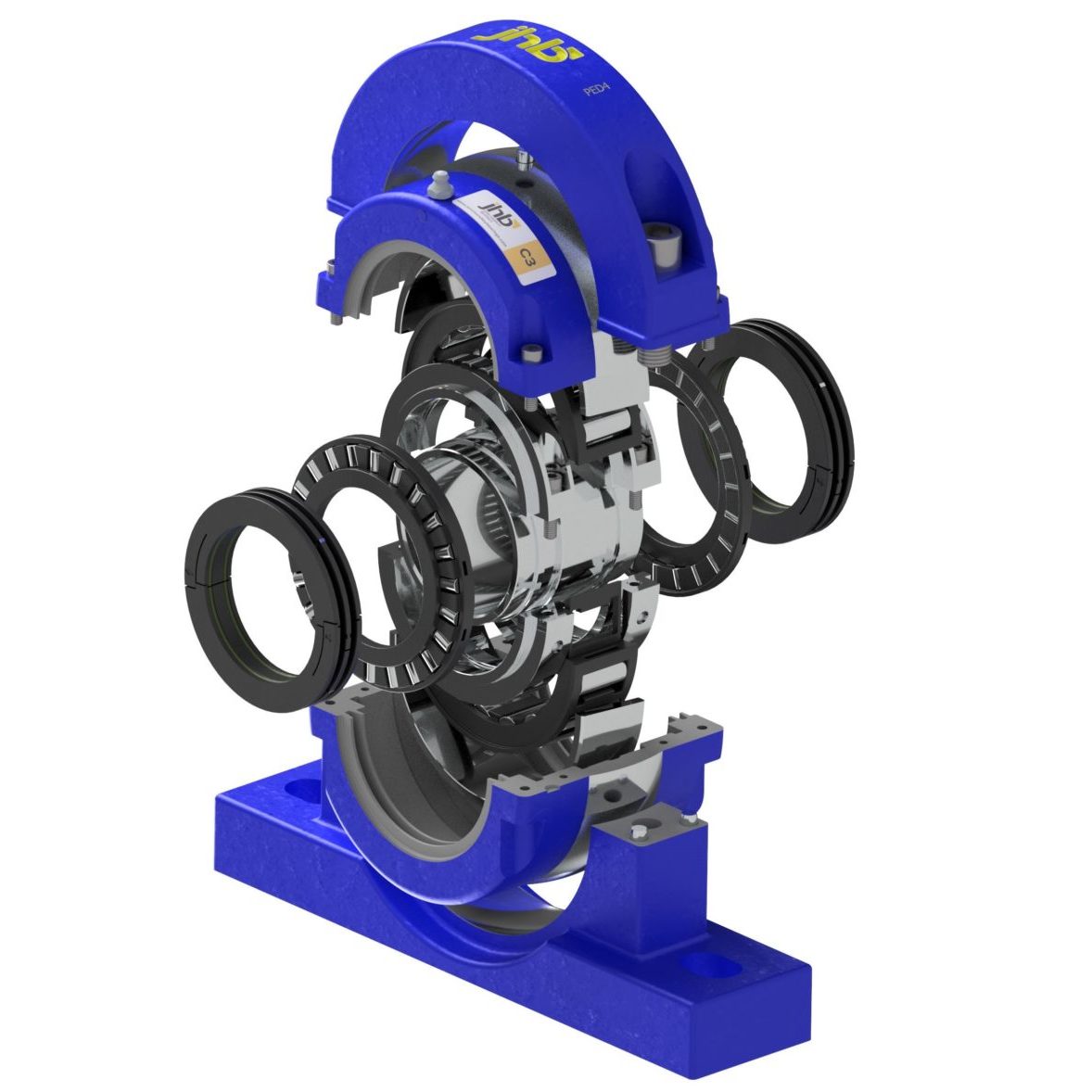

The entire split bearing has been designed around the bearing cage and the numbers are quite breathtaking; the patent-pending bearing cage, Rollertrain®, has an increased radial capacity of up to 70% and an increased axial capacity of up to 1000% of any other split bearing in the world. Indeed, the bearing cage has already been nominated for the prestigious Industrial Product Application Award at the annual TCT Awards. The dramatic capacity increases allow the JHB Split Bearing to replace three series of split bearings with a single series which covers almost all existing requirements.

Independent Axial Load

The rolling elements within current split bearings are unable to properly accommodate axial and radial loads independently; they only allow for a radial load with a significantly downgraded axial load capacity. The JHB Split Bearing is able to accommodate both loads independently and in so doing enables for the first time the calculation of an axial L10 life. This is a capability that was previously impossible and offers a new dimension of flexibility and design freedom.

Disrupting the market

It is very difficult to overstate the importance of these new bearings. JHB and Bowman have done what good innovators do and have taken an existing idea, added to it, made it more efficient and improved it exponentially. The bearing offers improvements and added value across the board compared to any other split bearing and genuinely has the potential to severely disrupt the market by offering design engineers a more flexible, durable and cost-effective alternative to the original split bearings currently available.